Alamat:

No.233-3 Jalan Yangchenghu, Taman Perindustrian Xixiashu, Daerah Xinbei, Bandar Changzhou, Wilayah Jiangsu

• Salutan berlian digunakan dengan teknologi canggih untuk mendapatkan lekatan salutan yang lebih baik.

• Teknologi pengisaran lanjutan memastikan keserasian ultra tinggi, rintangan suhu tinggi dan rintangan haus dalam diameter berkesan ultra panjang.

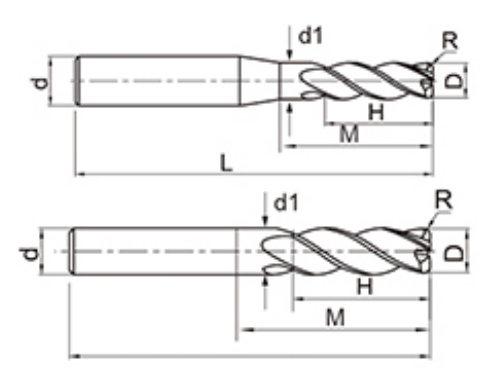

| Model | Dimensi Asas(mm) | ||||||

| D | R | H | M | d1 | d | L | |

| NNS-4R-D3R0.2H20 | 3.0 | R0.2 | 20 | 9 | 2.8 | 3 | 60 |

| NNS-4R-D3R0.5H20 | 3.0 | R0.5 | 20 | 9 | 2.8 | 3 | 60 |

| NNS-4R-D4R0.2H25 | 4.0 | R0.2 | 25 | 12 | 3.7 | 4 | 60 |

| NNS-4R-D4R0.5H25 | 4.0 | R0.5 | 25 | 12 | 3.7 | 4 | 60 |

| NNS-4R-D6R0.2H35 | 6.0 | R0.2 | 35 | 20 | 5.6 | 6 | 75 |

| NNS-4R-D6R0.5H35 | 6.0 | R0.5 | 35 | 20 | 5.6 | 6 | 75 |

| NNS-4R-D6R1.0H35 | 6.0 | R1.0 | 35 | 20 | 5.6 | 6 | 75 |

| NNS-4R-D8R0.5H35 | 8.0 | R0.5 | 35 | 25 | 7.6 | 8 | 75 |

| NNS-4R-D8R1.0H35 | 8.0 | R1.0 | 35 | 25 | 7.6 | 8 | 75 |

| NNS-4R-D10R0.5H50 | 10.0 | R0.5 | 50 | 35 | 9.6 | 10 | 100 |

| NNS-4R-D10R1.0H50 | 10.0 | R1.0 | 50 | 35 | 9.6 | 10 | 100 |

| NNS-4R-D12R0.5H50 | 12.0 | R0.5 | 50 | 35 | 11.4 | 12 | 100 |

| NNS-4R-D12R1.0H50 | 12.0 | R1.0 | 50 | 35 | 11.4 | 12 | 100 |

| NNS-4R-D16R0.5H80 | 16.0 | R0.5 | 80 | 60 | 15.6 | 16 | 150 |

| NNS-4R-D16R1.0H80 | 16.0 | R1.0 | 80 | 60 | 15.6 | 16 | 150 |

| NNS-4R-D3R0.5H30 | 3.0 | R0.5 | 30 | 9 | 2.8 | 3 | 75 |

| NNS-4R-D4R0.5H30 | 4.0 | R0.5 | 30 | 12 | 3.7 | 4 | 75 |

| NNS-4R-D3R0.5H30 | 3.0 | R0.5 | 30 | 9 | 2.8 | 3 | 100 |

| NNS-4R-D4R0.5H30 | 4.0 | R0.5 | 30 | 12 | 3.7 | 4 | 100 |

| NNS-4R-D6R0.2H40 | 6.0 | R0.2 | 40 | 25 | 5.6 | 6 | 100 |

| NNS-4R-D6R0.5H40 | 6.0 | R0.5 | 40 | 25 | 5.6 | 6 | 100 |

| NNS-4R-D6R1.0H40 | 6.0 | R1.0 | 40 | 25 | 5.6 | 6 | 100 |

| NNS-4R-D8R0.5H40 | 8.0 | R0.5 | 40 | 30 | 7.5 | 8 | 100 |

| NNS-4R-D8R1.0H40 | 8.0 | R1.0 | 40 | 30 | 7.5 | 8 | 100 |

| NNS-4R-D6R0.2H50 | 6.0 | R0.2 | 50 | 35 | 5.6 | 6 | 150 |

| NNS-4R-D6R0.5H50 | 6.0 | R0.5 | 50 | 35 | 5.6 | 6 | 150 |

| NNS-4R-D6R1.0H50 | 6.0 | R1.0 | 50 | 35 | 5.6 | 6 | 150 |

| NNS-4R-D8R0.5H60 | 8.0 | R0.5 | 60 | 40 | 7.5 | 8 | 150 |

| NNS-4R-D8R1.0H60 | 8.0 | R1.0 | 60 | 40 | 7.5 | 8 | 150 |

| NNS-4R-D10R0.5H60 | 10.0 | R0.5 | 60 | 40 | 9.4 | 10 | 150 |

| NNS-4R-D10R1.0H60 | 10.0 | R1.0 | 60 | 40 | 9.4 | 10 | 150 |

| NNS-4R-D12R0.5H70 | 12.0 | R0.5 | 70 | 50 | 11.6 | 12 | 150 |

| NNS-4R-D12R1.0H70 | 12.0 | R1.0 | 70 | 50 | 11.6 | 12 | 150 |

Siri NNS-4R menampilkan reka bentuk hidung bulat empat seruling, menggabungkan pemesinan berketepatan tinggi dengan ketahanan unggul. Bentuk hidung bulat meningkatkan rintangan hentaman dan mengurangkan kepekatan tekanan semasa pemotongan, menjadikannya sangat berkesan untuk pemesinan grafit. Untuk menangani sifat rapuh grafit, geometri tepi alat telah dioptimumkan untuk meminimumkan rintangan pemotongan dan meningkatkan kestabilan.

Dengan salutan berlian berprestasi tinggi, alat ini menawarkan lekatan yang dipertingkatkan, meningkatkan rintangan haus dengan ketara dan toleransi suhu tinggi. Ini memastikan kelebihan tajam walaupun di bawah pemesinan berkelajuan tinggi yang berpanjangan. Pengilangan ketepatan memastikan ketumpuan ultra tinggi, mengurangkan kehabisan alat dan memberikan kualiti kemasan permukaan yang unggul.

Siri ini menyediakan rangkaian komprehensif diameter, panjang pemotongan, diameter batang dan pilihan jejari untuk menampung pelbagai keperluan pemesinan. Sama ada untuk ukiran yang rumit atau pemotongan berskala besar, terdapat spesifikasi ideal yang tersedia, memastikan fleksibiliti dan kecekapan pemesinan untuk acuan grafit dan komponen ketepatan.

Penubuhan perusahaan

Pekerja

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are 4 Flute Round Nose End Mills untuk Pemesinan Grafit Suppliers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional 4 Flute Round Nose End Mills untuk Pemesinan Grafit Factory. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Kami akan membalas anda dalam masa 12 jam selepas menerima pertanyaan pada hari bekerja.

Kami adalah pengilang, kami menghasilkan dan menjual sendiri.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional 4 Flute Round Nose End Mills untuk Pemesinan Grafit Suppliers.

Produk kami meliputi hampir keseluruhan industri acuan, industri pertahanan, industri aeroangkasa, industri automotif, produk elektronik dan bidang lain.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom 4 Flute Round Nose End Mills untuk Pemesinan Grafit.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are 4 Flute Round Nose End Mills untuk Pemesinan Grafit Factory

Pertama, selepas setiap proses, kami menjalankan pemeriksaan yang sepadan. Untuk produk akhir, kami akan menjalankan 100% pemeriksaan penuh mengikut keperluan pelanggan dan piawaian antarabangsa;

Kemudian, kami mempunyai peralatan ujian terkemuka yang canggih dan lengkap dalam industri, seperti penganalisis spektrum, mikroskop metalografi, dll., yang boleh memastikan kestabilan dan konsistensi alat pemotong, sambil memenuhi keperluan ujian ketepatan tinggi pelanggan untuk alat pemotong.

Apabila sebut harga, kami akan mengesahkan dengan anda kaedah transaksi, FOB, CIF, CNF atau pilihan lain. Apabila menghasilkan secara pukal, kami biasanya membuat bayaran pendahuluan 30% dahulu, dan kemudian membayar baki yang tinggal selepas pembentangan bil muatan. Kami kebanyakannya menggunakan T/T sebagai kaedah pembayaran, tetapi L/C juga boleh diterima.